For all exterior commercial and public centre’s

Heavy Duty

To meet the requirements of high-traffic public utilities, specially designed Glide Mass Transit Escalators are suited for continuous large crowds, indoor or outdoor, and operate perfectly under all climatic conditions.

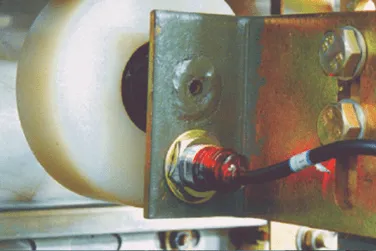

Drive-Chain Contact

This contact monitors the drive-chain for breakage. When actuated, the contact will stop the escalator.

Phase Monitor

A safety feature which monitors the main power supply and disables on event of phase failure or reversal.

Maintenance locking device

The normal key start will be invalid. The inspection sockets in up and down machine room aren’t usable at same time.

Speed Monitor

Monitors the speed of the flywheel as well as avoids reversing. Will stop for speed over 120% or under 80%.

| Installation | Indoor/semi-outdoor/outdoor |

|---|---|

| Inclination | 30°/35° |

| Step Width | 600/800/1000 mm |

| Horizontal step run | 800/1200/1600 mm |

| Speed | 0.5/0.65 m/s |

| Capacity | 3600/4800/6000 pers/hr for step width 600/800/1000 mm respectively |

| Power Supply | AC 3-phase, 50/60 Hz |

| Lighting Supply | AC Single-phase, 50/60 Hz |

| Balustrade Design | Vertical safety glass (10mm safety tempered glass) or inclined Stainless Steel |

|---|---|

| Balustrade Profile | Hairlne ST/ST |

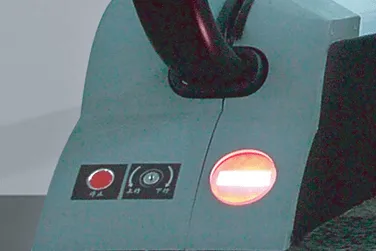

| Handril | Black, other colours optional |

| Deckings | Hairline ST/ST |

| Skirting Panel | Hairline ST/ST |

| Step | Die-cast aluminium, painted silver grey, optional black |

| Landing Plate | Etched ST/ST with anti-slip pattern |

| Operation Panel | Red emergency stop button, up/down key switches |

Brochure

Comercial

Energy Efficient, Green, BMS/RMS Compatible, Aesthetically rich and durable lifts and escalators.

To get to know more about Glide Escalators, download brochure.

Send download link to:

Escalators for Commercial places

Complies with European code EN 115 and international codes

Escalators for public places

Weatherproofing & unique balustrade design conform customer specs

Walkalators for Public places

Specially designed to meet high-traffic utilities, indoor or outdoorGet to know special advantages of Glide Escalators

Additional Features

Safety is our utmost priority

Safety FeaturesCover and Keep safe

Cover the Escalator area & protect from water entry.

Press STOP when needed

Use the “STOP” button if incase of any emergency.

Ensure you protect the gaps

Protect the entrance side gaps on both ends to ensure safety of the passengers.

Ensure proper usage

Prevent misuse or vandalism of the escalator.

Drive-Chain Contact

This contact monitors the Drive-Chain for breakage. When actuated, the contact will stop the escalator

Skirting Contacts

These contacts have been installed at both the top and bottom of the escalator at the transition curve. If an object gets caught between the step and the skirting panel, the resultant pressure on the skirting panel will actuate one of these contacts, thereby disabling and switching off the escalator

Handrail Entry Contacts

The handrail entry points are located for beneath the head of the balustrade. The handrail entry contacts are so positioned that if there is any danger of an object becoming wedged in the handrail entry points, a contact will actuate and switch off the escalator

Step Chain Contacts

Located in the lower step-reversing compartment, these contacts monitors the step chains for elongation, breakage or shortening of one or both step chains. When actuated, they will disable and switch off the escalator.

Maintenance Locking Device

The normal key start function will be invalid while maintenance Lock device is in use. The inspection socket in up and down machine room cannot be used at the same time.

Alarm Buzzer

The buzzer is located in up/down machine room, which can call passenger’s attention when starting the escalator

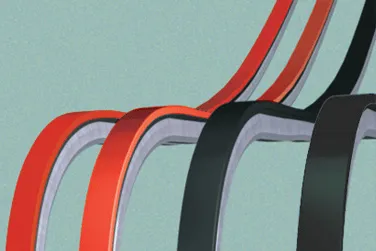

Speed Monitor with Anti-reverse Function

Fixed at the bottom of the brake, it monitors the speed of flywheel as well as avoids reversing, Will stop escalator in case rated speed is over 120% or under 80%

Step Anti-static Brush

Located in the truss, under th step near the linear end. Eliminates step static

Step Missing Device

Two sensors are fixed, at upper/lower return sections, to receive pulse signals from steps passig by. If a step is missing, the escalator is stopped before missing step enters combo plate

Step Sag Contacts

fIxed at the start sections of both inclined upper and lower transition curves, it will be actuated to stop escalator in case step(including step roller) sags more than 3mm

Phase Monitor

This is a safety feature which monitors the main power supply and disables the escalator in the event of phase failure or phase reversal

Motor Overload and Overheat Relay

This relay monitors the motor’s working condition. In case of motor overload of overheating, the escalator should be stopped

Comb Contacts

If a foreign object is caught between the comb plates and the steps, the resulting pressing action will move one of the comb plates backwards and actuate a safety contact, thereby switching off the escalator

Step Gap Illumination

Special green laps in the form of fluorescent tubes, ounted on both the top and bottom of the escalator, make the individual steps clearly discernible. Especially at the horizontal runs. Therefore boarding the escalator is made much easier for the young, elderly and inexperienced users

Handrail Anti-static Roller

Located under both ends of the handrail in the truss

Emergency Stop Buttons

Built into the balustrade skirting at the upper and lower ends of the escalator, the emergency stop button may be used to switch off the escalator manually

Step Reversing Fences

The fence is fixed at the end of step reversing point in the machine room for safety

Service Brake Release Contact

This contact is fixed at both brake arms to monitor whether the brake is open or not. If the brake operates abnormally, the escalator will not start and alarm will sound

Specifications

| Type | Fet | FEF | FEW |

|---|---|---|---|

| Inclination | 10°, 11°, 12° | 10°, 11°, 12° | 0° – 6° |

| Pallet Width | 800/1000 | 800/1000 | 1000/1200/1400 |

| Horizontal Pallet run | 400 (upper landing) | 400 | N/A |

| Speed | 0.5 | 0.5 | 0.5 |

| Speed | 3600/4800/6000 for pallet width 600, 800 1000, 1200, 1400 mm respectively | ||

| Power Supply | AC 3-phase, 50/60 Hz. | ||

| Lighting Supply | Ac Single-phase, 50/60 Hz. | ||